In the fast-paced world of manufacturing, efficiency and precision are paramount. As industries strive to meet increasing consumer demands, the role of technology becomes ever more critical. Among the myriad of innovations that have transformed production lines, filling machines stand out as a cornerstone of modern manufacturing processes. These machines, designed to accurately fill containers with liquids, powders, or granules, are essential in sectors ranging from food and beverage to pharmaceuticals and cosmetics. By automating the filling process, companies can significantly boost productivity, reduce waste, and ensure consistent product quality. This article delves into the intricacies of filling machines, exploring how they enhance operational efficiency and the various types available to meet diverse industrial needs.

Boosting Productivity with Automated Filling Equipment

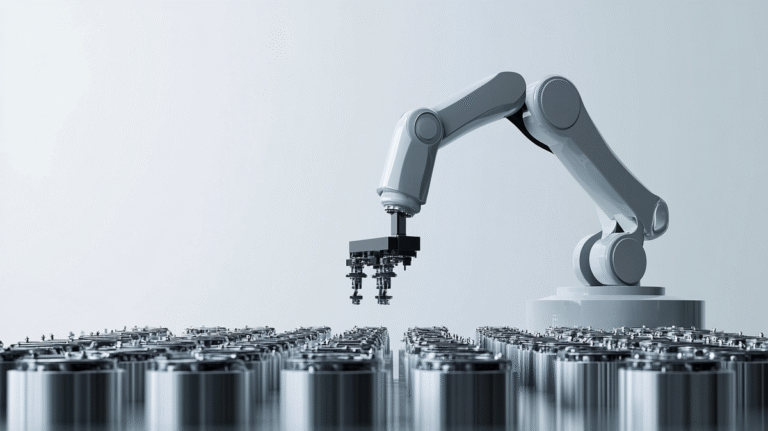

The integration of automated filling equipment into production lines has revolutionized the way industries operate. By replacing manual filling methods with automated systems, companies can achieve higher throughput and maintain consistent product quality. Automated filling machines are designed to handle a wide range of products, from viscous liquids to fine powders, ensuring that each container is filled with precision and accuracy.

One of the primary advantages of automated filling machines is their ability to operate continuously with minimal human intervention. This not only reduces labor costs but also minimizes the risk of human error, which can lead to product inconsistencies and waste. Furthermore, automated systems can be easily integrated with other production line equipment, such as capping and labeling machines, to create a seamless and efficient manufacturing process.

The use of industrial filling machines is particularly beneficial in high-volume production environments. These machines are capable of filling thousands of containers per hour, making them ideal for large-scale operations. Additionally, they can be customized to accommodate different container sizes and shapes, providing flexibility and versatility to manufacturers.

Types of Filling Machines and Their Applications

Filling machines come in various types, each designed to handle specific products and applications. The most common types include liquid filling machines, powder filling machines, and granule filling machines. Liquid filling machines are used in industries such as food and beverage, pharmaceuticals, and cosmetics, where they fill bottles, jars, and other containers with liquids ranging from water to viscous syrups.

Powder filling machines, on the other hand, are used for products like spices, flour, and pharmaceutical powders. These machines are equipped with specialized mechanisms to ensure accurate and consistent filling, even with fine and free-flowing powders. Granule filling machines are designed for products like grains, seeds, and pellets, and are often used in the agricultural and chemical industries.

Each type of filling machine is equipped with features that cater to the specific needs of the product being filled. For instance, liquid filling machines may include nozzles that prevent dripping and spillage, while powder filling machines may have dust extraction systems to maintain a clean working environment. The choice of filling machine depends on factors such as product viscosity, container type, and production volume.

Future Trends in Filling Machine Technology

As technology continues to advance, the future of filling machines looks promising. Innovations such as smart sensors, IoT integration, and machine learning are set to enhance the capabilities of filling machines, making them more efficient and adaptable. Smart sensors can monitor the filling process in real-time, providing valuable data that can be used to optimize production and reduce downtime.

IoT integration allows filling machines to communicate with other equipment on the production line, enabling seamless coordination and control. This connectivity also facilitates predictive maintenance, where potential issues can be identified and addressed before they lead to costly breakdowns. Machine learning algorithms can analyze production data to identify patterns and suggest improvements, further enhancing the efficiency of filling operations.

In conclusion, filling machines are an indispensable component of modern manufacturing. By automating the filling process, these machines help industries boost productivity, reduce waste, and maintain high product quality. As technology continues to evolve, filling machines will become even more sophisticated, offering new opportunities for manufacturers to enhance their operations and meet the demands of a rapidly changing market.